The domestic market price of methyl ethyl ketone (MEK) is showing a trend of regional convergence, with current prices at a low level for the year, reflecting that the market has not yet formed a clear directional trend amid the supply-demand game between supply and demand. Since June, major domestic suppliers such as the large plant in Huizhou, Guangdong, the large plant in Anhui, and the large plant in Zibo, Shandong, have collectively reduced production, leading to a sharp decline in supply. Changes in their operating rates have a significant impact on the market's supply-demand balance. Downstream industries of MEK, including pulp, leather, and adhesive sectors, are in their traditional low consumption season. Major pulp plants are maintaining production at planned volumes, while small and medium-sized factories are operating at low levels, keeping inventories at medium to low levels and primarily engaging in just-in-time replenishment. In mid-to-early June, after MEK prices fell to near cost levels, downstream users and traders entered the market to buy at low prices. Coupled with a concentrated release of overseas demand before the deadline for the U.S.'s global reciprocal tariffs, export orders for leading enterprises increased, alleviating supply pressure. However, after July 8, changes in tariff policies made it difficult for the strong export momentum to continue. Overall, the MEK market is at a critical juncture in the supply-demand tug-of-war, with prices fluctuating. Production reductions and maintenance on the supply side provide short-term support, but weak domestic demand and declining export competitiveness pose long-term pressures. Moving forward, it is essential to closely monitor the operating dynamics of leading enterprises, changes in raw material costs, and the pace of policy-driven favorable developments. The market is likely to continue its oscillating pattern amid the interplay of "weak realities and strong expectations."

Read More

Ethyl acetate in East China, affected by plant maintenance, some enterprises have slightly raised prices. In South China, the market is in a wait-and-see mood with insufficient demand support. In North China, tight supply has pushed up prices. Capacity utilization rate: Last week, the capacity utilization rate of ethyl acetate was 45.53%, down 1.64 percentage points from the previous week, mainly due to plant maintenance and weak demand. In 2025, 480,000 tons of new capacity is planned to be added, but the commissioning progress has been delayed by sluggish market conditions, with some plants postponing start-ups. Demand-wise, traditional sectors such as coatings and printing inks remain weak, with downstream procurement mainly based on rigid demand and high price sensitivity. Ethyl acetate exports continue to perform well, with single-month export volume in February 2025 hitting a ten-year high . The ethyl acetate market is characterized by regional differentiation, cost support, and weak demand coexisting. Prices have risen slightly, but the overall market still faces pressure from overcapacity, with exports serving as the main growth driver.

Read More

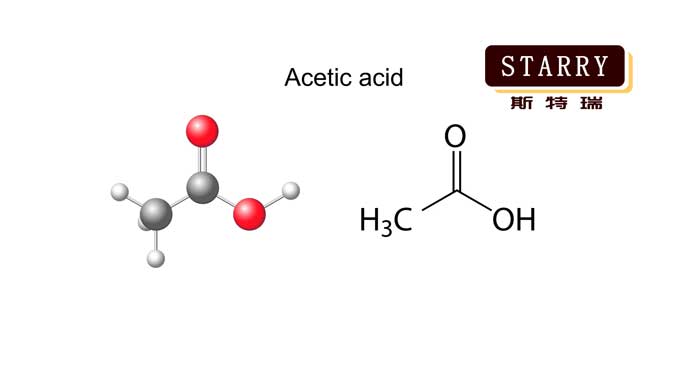

Acetic acid, also known as ethanoic acid, is a colorless liquid organic compound with a distinctive sour taste and pungent smell. It has a wide range of applications in various industries. Here are some of the main uses of acetic acid: 1. Vinegar Production: Acetic acid is the main component of vinegar, making up about 4-18% of its content. It gives vinegar its characteristic taste and smell. 2. Chemical Production: Acetic acid is used in the production of a number of chemical compounds. For example, it is used to produce vinyl acetate monomer (VAM), which is used in the manufacture of polymers for adhesives, paints, and films. 3. Food Industry: Acetic acid is used as a food additive and preservative. It helps to prevent the growth of harmful bacteria in food. 4. Textile Industry: Acetic acid is used in the dyeing and finishing processes of the textile industry. It helps to promote color retention and fabric strength. 5. Pharmaceutical Industry: Acetic acid is used in the production of certain medications, including aspirin and other pain relievers. 6. Cleaning Products: Acetic acid is used in a variety of cleaning products due to its ability to cut through grease and remove mineral deposits. 7. Photography: Acetic acid is used as a stop bath in photography. The acid halts the development process and prevents the image from changing further. Please note that acetic acid can be corrosive and should be handled with care. Always follow safety guidelines when using products containing acetic acid.

Read More

Aniline is one of the most essential amine substances. It is mainly used to manufacture dyes, drugs, and resins, as a rubber vulcanization accelerator, etc. It can also be used as a black dye by itself. Its derivative methyl orange can be used as an indicator for acid-base titration. The industrial production of aniline involves the following two steps. First, benzene is nitrated at 50-60 °C in a mixture of concentrated sulfuric acid and concentrated nitric acid to give nitrobenzene; the latter is then catalytically reduced by hydrogenation (reaction temperature usually between 200-300 °C). Specification: Appearance and properties: Colorless or slightly yellow oily liquid with a strong odor. CAS: 62-53-3 UN: 1547 Molecular formula: C6H7N Melting point (℃): -6.2 Boiling point (℃): 184.4 Flash point (℃): 70 Density: 1.02 g/cm³ Solubility: slightly soluble in water, ethanol, ether, and benzene.

Read More

DMF is a transparent liquid, a chemical that is miscible with water and most organic solvents. DMF is also known as dimethylformamide. Dmf is very hygrometric and can be mixed with water, alcohol, ether, ester, ketone, unsaturated hydrocarbon, and aromatic hydrocarbon, but does not dissolve with gasoline, alkane, cyclohexane, and other saturated hydrocarbons. DMF is mainly used for producing, storing, and transporting leather, footwear, and textiles. Mildew protects and preserves food, cereals, fruits and vegetables, feed, and tobacco. In addition, some factories spray DMF on products or packaging for disinfection and mildew protection before exporting. If easily allergic after contact with skin can lead to skin eczema and burns. DMF is stored in a cool, ventilated storage room. The temperature of the warehouse should not exceed 37℃. Keep the container sealed away from fire and heat sources. It should be stored separately from oxidants, reducing agents, halogens, etc., with explosion-proof lighting and ventilation facilities. Do not use mechanical equipment and tools that are prone to sparks.

Read More